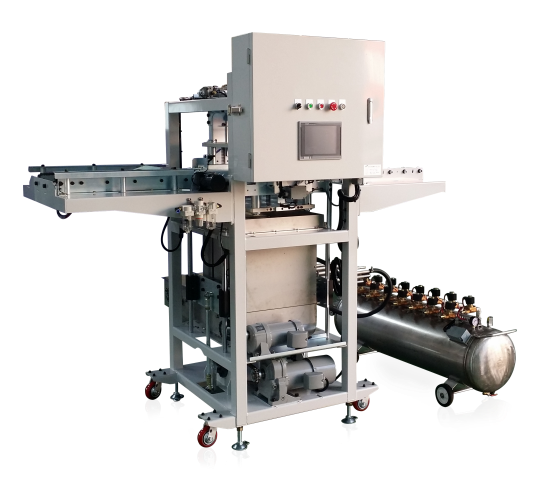

Unbottling Machine (Air Type)

A) Description : The machine removes the waste medium in the bottle by using high-pressure air momentarily after harvesting.

B) Process Capacity (per hour) : 9,000 ~ 12,000 bottles

C) Bottles to be used : 850cc ~ 1,500cc

D) External Size : 2,100mm(L) * 1,540mm(W) * 1,820mm(H)

E) Special Features :

ㅇ With the basket being able to be put and discharged at the same time with unbottling operation, the process

speed is high.

ㅇ The turning process of basket is possible without up-and-down operation, so the process speed is high.

ㅇ The air injection pipes are strong durable and corrosion by using stainless material.

ㅇ The residual quantity is discharged from a bottle inside by twice air injection.

ㅇ The Air injection timing can be simply adjusted by sensor.

ㅇ When alarm sounds, troubles and measures can be checked on the screen.

ㅇ With 63 type of plate rotating worm decelerator being used, there are no minor troubles in the machine.

ㅇ Daily quantity of process can be checked and the setpoint can be operated on the screen.

ㅇ Inverters are adopted to all reduction gear motors.

F) Main parts in the machine : Motor (Samyang Decelerator, GGM), Inverter (Mitsubishi), Cylinder (SMC), PLC (LS),

Touch Screen (TOP), Sensor (Autonix), etc.

G) Operating Conditions : Power consumption 3kw, Pneumatic pressure not less than 6~7kgf/㎠(Machine),

Not less than 1,000L(Air auxiliary tank)