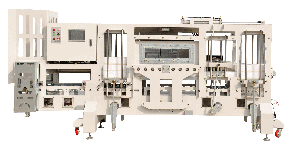

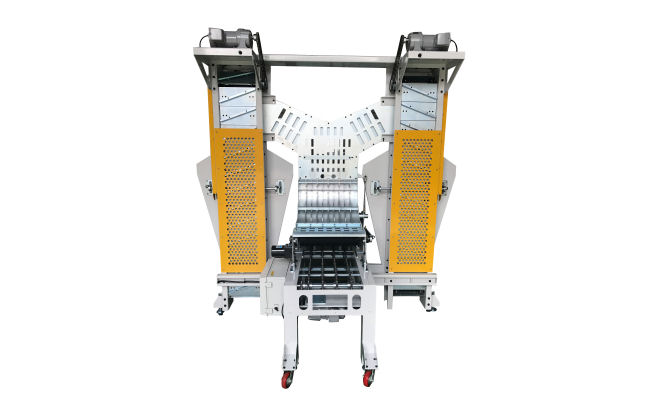

- Capping Machine

ㆍDescription : The machine caps the bottles after bottling.

ㆍProcess Capacity (per hour) : 8,000 ~ 12,000 bottles

ㆍBottles to be used : 850cc ~ 1500cc

ㆍExternal Size : 2,280mm(L) x 1,480mm(W) x 2,930mm(H)

ㆍExternal Size : 1,700mm(L) x 2,400mm(W) x 2,350mm(H)

ㆍSpecial Features– With the cap discharging part being fixed by a spring, the machine is semi-permanent.

(Old type of machines use brushes.)

– Many quantity of caps can be stored in the big box behind the machine, being ready to be put.

– Adopting an inverter, cap supply conveyor is controlled with stability.

– With the chain being used, basket transfer conveyor is less slippery.

– Basket guide holds bottle neck to make the bottles less pushed.

– By adopting a timer and a sensor in putting caps, the quantity of cap input can be controlled.ㆍMain parts in the machine : Atachi chain (Korea Chain), Motor (Samyang Decelerator, GGM),

Rubber roller, Inverter (Hitachi), Timer, Sensor (Autonix), etc.ㆍOperating Condition : Power consumption 1.5kw